Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Doctor Blade Film Applicator: A Comprehensive Guide

A doctor blade film applicator is a specialized tool or machine used to apply thin, uniform layers of liquid coatings, adhesives, or films onto surfaces. This technique ensures precise control over the thickness and consistency of the applied material, making it widely used in industries such as printing, packaging, electronics, automotive, and manufacturing.

Below is an indepth exploration of doctor blade film applicators, including their working principles, types, applications, advantages, limitations, and key considerations.

●1. What Is a Doctor Blade Film Applicator?

A doctor blade film applicator uses a flexible or rigid blade (the "doctor blade") to spread a controlled layer of material onto a substrate. The blade regulates the thickness of the coating by maintaining a consistent gap between itself and the surface being coated. This method ensures uniformity and minimizes waste.

●2. How Does a Doctor Blade Film Applicator Work?

A. Key Components

1. Doctor Blade:

A flat, sharpedged blade made of materials like stainless steel, plastic, or elastomers.

Controls the thickness of the applied film by regulating the gap between the blade and the substrate.

2. Coating Reservoir:

Holds the liquid coating or adhesive to be applied.

3. Application Roller:

Transfers the material from the reservoir to the substrate.

4. Substrate Handling System:

Moves the substrate (e.g., paper, plastic, metal) beneath the blade at a controlled speed.

5. Adjustment Mechanism:

Allows finetuning of the blade angle, pressure, and distance from the substrate.

B. Working Process

1. The substrate moves beneath the application roller.

2. The coating material is transferred from the reservoir to the roller.

3. The doctor blade skims the excess material off the roller, leaving only a thin, uniform layer.

4. The coated substrate continues moving forward for drying, curing, or further processing.

●3. Types of Doctor Blade Film Applicators

A. Manual Doctor Blade Applicators

Operated by hand, suitable for smallscale or laboratory applications.

Commonly used for testing and prototyping.

B. SemiAutomatic Doctor Blade Applicators

Combine manual operation with automated features like speed control or blade adjustment.

Ideal for mediumscale production environments.

C. Fully Automatic Doctor Blade Applicators

Entirely automated systems for highvolume production.

Often integrated into larger manufacturing lines for consistent performance.

●4. Applications of Doctor Blade Film Applicators

A. Printing Industry

Applying ink or varnish coatings on paper, cardboard, or plastic substrates.

Used in flexographic, gravure, and screen printing processes.

B. Packaging Industry

Coating adhesives on packaging materials for sealing or laminating.

Applying protective layers to enhance durability and appearance.

C. Electronics Industry

Depositing conductive or insulating films on circuit boards.

Applying thermal management coatings to improve heat dissipation.

D. Automotive Industry

Coating paints, sealants, or anticorrosion layers on vehicle components.

Applying decorative films on interior and exterior surfaces.

E. Medical Industry

Laminating medical devices with sterile or antimicrobial coatings.

Applying precision coatings on diagnostic tools and equipment.

●5. Advantages of Doctor Blade Film Applicators

1. Precision and Uniformity:

Ensures consistent film thickness across the substrate.

2. CostEffectiveness:

Minimizes material waste compared to other coating methods.

3. Versatility:

Compatible with a wide range of materials, including liquids, pastes, and gels.

4. Customizability:

Adjustable blade settings allow for tailored applications based on specific requirements.

5. Ease of Use:

Userfriendly designs make them accessible for both professionals and hobbyists.

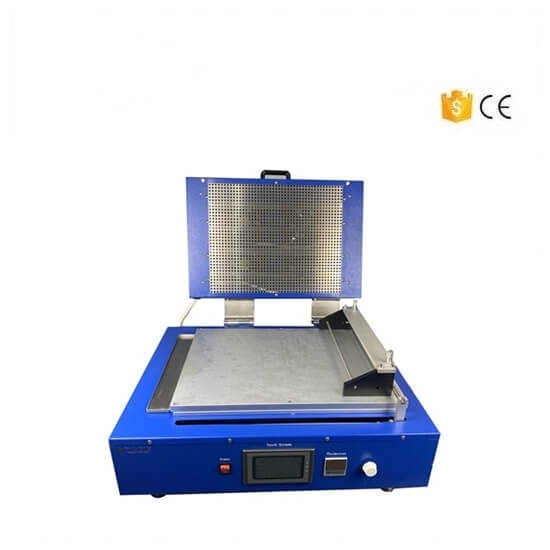

Vacuum Electrode Coater

●6. Limitations of Doctor Blade Film Applicators

1. Material Constraints:

Certain materials may not adhere well to the substrate or may clog the system.

2. Blade Wear:

Continuous use can cause wear or damage to the blade, affecting performance.

3. Setup Time:

Adjusting the blade and calibrating the system can be timeconsuming.

4. Surface Restrictions:

May not work effectively on uneven or irregular surfaces.

●7. Factors Influencing Performance

| Factor | Impact on Performance |

|||

| Blade Angle | Affects the thickness and uniformity of the applied film. |

| Blade Pressure | Determines how much material is removed during application. |

| Substrate Speed | Faster speeds may reduce precision; slower speeds increase accuracy. |

| Coating Viscosity | Higher viscosity coatings require adjustments to blade settings. |

| Environmental Conditions | Temperature and humidity can influence coating behavior. |

●8. Popular Manufacturers of Doctor Blade Film Applicators

| Manufacturer | Key Features |

|||

| 3M | Offers a range of manual and semiautomatic applicators for diverse applications. |

| Tesa | Specializes in adhesive film applicators for industrial use. |

| ITW Rework | Provides advanced film applicators for electronics and packaging. |

| Apollo Automation | Known for customizable and automated film application solutions. |

●9. Maintenance Tips for Doctor Blade Film Applicators

1. Regular Cleaning:

Remove dried residues and debris from the blade and application roller.

2. Blade Inspection:

Check for wear, nicks, or damage to ensure consistent performance.

3. Lubrication:

Apply lubricants to moving parts as recommended by the manufacturer.

4. Calibration:

Periodically verify and adjust blade angle, pressure, and substrate speed settings.

5. Storage:

Store the applicator in a clean, dry environment when not in use.

●10. Future Trends in Doctor Blade Film Applicators

1. Automation and Robotics:

Integration of robotics for increased efficiency and precision in largescale operations.

2. Smart Technology:

Realtime monitoring and data analytics for optimizing performance.

3. Sustainability:

Development of ecofriendly coatings and materials compatible with existing applicators.

4. UserFriendly Interfaces:

Advanced touchscreens and intuitive controls for easier operation.

●11. Conclusion

Doctor blade film applicators are essential tools for achieving precise and uniform coating applications across various industries. Their ability to regulate film thickness and minimize waste makes them indispensable for modern manufacturing and customization processes. While they come with certain limitations, ongoing advancements continue to enhance their functionality, efficiency, and environmental friendliness.

If you're considering purchasing or using a doctor blade film applicator, carefully evaluate your needs, budget, and longterm goals to select the right system for your operations.

For further details or assistance in choosing the best doctor blade film applicator, feel free to ask!

+86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588